CNC drilling tapping center-The first choice for CNC machine tools

CNC Machine New Breakthrough - Tapping, Drilling, Milling All in One

With 30 years of craftsmanship heritage and innovative integration, we proudly introduce the all-new CNC Drilling and Tapping Machine - BEECNC. Combining drilling, tapping, and milling functions, it not only enhances your processing efficiency but also fully satisfies your diverse needs. It guarantees to inject fresh vitality into your machining business, further elevating your competitiveness.

DESCRIPTION

High-Precision CNC Machines for Large-Batch Production

Compact machine center with 40 years of expertise, trusted by loyal clients and backed by international certifications. Perfect for drilling, tapping, and milling. Ideal as a tapping machine center for efficient, large-batch production.

Boosting Efficiency with Compact CNC Machines

Better CNC machining centers or compact machine tools: Faster, more stable, and energy-efficient with a lighter weightdesign.

6 Major Advantages

Our CNC machines focus on production efficiency, optimizing speed and quality from the very beginning. Choose BEECNC for a seamless, cost-effective manufacturing process that truly maximizes your results.

1.Space Savings :60% more compact than former model.

2.Energy Savings : Save 35% electricity and 50% compressed air consumption

Saves 35% on electricity and 50% on compressed air consumption.

3.Structural Rigidity : 15% structural enhancement by advanced FEA design

15% structural enhancement achieved through advanced FEA design.

4.Component Upgrades :

New spindle and guideways system

New spindle system and upgraded guideways.

5.Fast : 12% more daily output

Boosts daily output by 12%.

6.Quick Payback : Achieve higher returns with your investment.

CNC machines save space with a compact design.

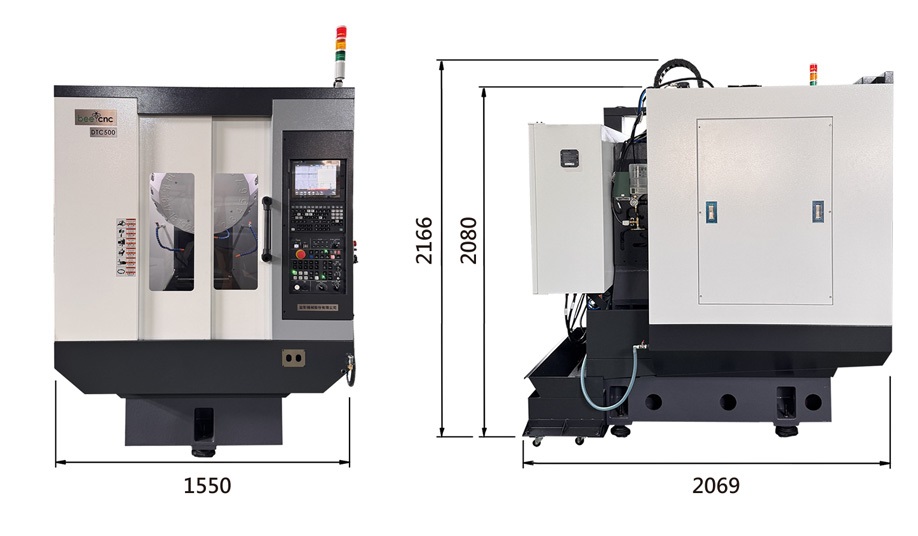

Dimensions: L162cm × W213cm × H216cm

Made in Taiwan with 100% Commitment.

40 Years of Innovation and Excellence

from Taiwan.

Your Ideal Partner for Industry 4.0 Smart Manufacturing.

Automatic system supports various robotic arms, reducing labor costs

CNC Machine Sales & Support

Beecnc – Built for Best Engineering, Exceptional Efficiency

-

Machining Capabilities :Compact CNC machine for drilling, tapping, and milling.

-

Wide Expandability :Flexible CNC machine center for diverse tasks.

-

High Stability : Reliable CNC machines with proven stability.

-

Special Pricing : Our affordable CNC machines offer Japanese-level quality at a competitive price, starting at $39,000 for Taiwanese models. Request a quotation today!

-

Added value :Custom jigs and fixtures for CNC integration.

-

Prompt service : Fast support for CNC machine stability.

-

Professional manufacturing : With 40 years of expertise, we specialize in Taiwan CNC machines, delivering precision and reliability to the global market.

左右滑動看表格

左右滑動看表格| Specifications | Unit | DTC-500 | ||||

| Travel | X axis travel | mm | 500 | |||

| Y axis travel | mm | 400 | ||||

| Z axis travel | mm | 330 | ||||

| Distance from spindle nose to work surface | mm | 150-480 | ||||

| Worktable | Worktable size | mm | 650*400 | |||

| Max. load (Average) | kg | 300 | ||||

| Work surface height (above ground) | mm | 800 | ||||

| Spindle | Taper type | BT-30 (Direct connection) | ||||

| Speed range | rpm | 12000 / 24000 (OPT) | ||||

| Feed rate | Rapid feed rate | m / min | X、Y、Z-48m / min | |||

| Cutting feed rate | m / min | X、Y、Z-10m / min | ||||

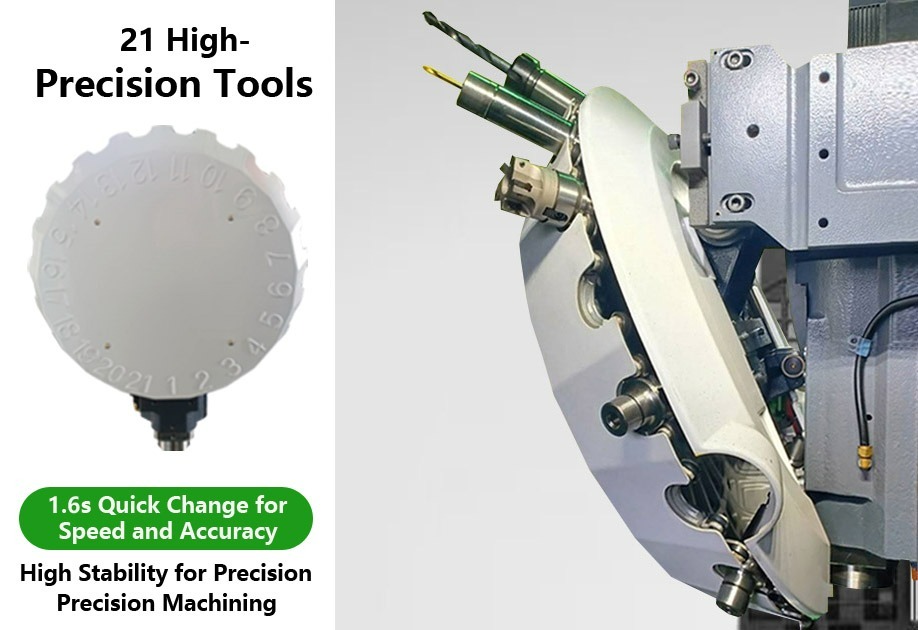

| Automatic tool changing system | Tool specifications | BT-30 | ||||

| Maximum tool diameter | mm | Ø80mm | ||||

| Number of tools | 21 | |||||

| Maximum tool length | mm | 250mm | ||||

| Tool weight | kg | 2Kg | ||||

| Spindle HP / KW | Spindle | KW | 3.7-7.5KW | |||

| X axis | HP / KW | 2.0HP / 1.5KW | ||||

| Y axis | HP / KW | 2.0HP / 1.5KW | ||||

| Z axis | HP / KW | 2.68HP / 2.0KW | ||||

| Controller System | Taiwan Delta, Japan Mitsubishi, and FANUC (three options available) | |||||

| Machine Weight | 2800kg | |||||

左右滑動看表格

左右滑動看表格

CE and TS standards、ISO 14955、Machine tools Environmental evaluation of machine tools

CNC Machine Center Optional Accessories

Optional accessories are sold separately. Contact us for details.

Add 4th axis

Add a 4th axis for 360° rotation and efficient multi-surface machining.

Tool Setter

Automatic tool setters are recommended for fully automated CNC operations.

Chip Conveyor

Ideal for compact CNC machines with limited space or automated chip disposal.

Coolant Through Spindle

Necessary for deep drilling or high depth-to-width ratio machining.

Oil cooler

Essential for CNC machines operating at high speeds for extended periods.

Oil Mist Collecto

Improves air quality during pure oil-based cutting operations.

6 Key Benefits of Choosing Our CNC Machine Center

Best Choice for CNC Machine Solutions

Welcome to Test the Machine.

Visit our factory to test CNC machines. Schedule your appointment today.Address: 412 No. 115 Kung Yei TIRD, Dali IDN ZONE, Dali District, Taichung City, Taiwan, R.O.C.

High Stability

Proven stability and durability with over 70 units sold since 2019

Service Techs Support

Our team of factory-trained and certified technicians possesses extensive local manufacturing expertise and is ready to provide you with top-notch CNC machines service. Feel free to contact us at +886-4-24930678 or reach out via Facebook Messenger or WhatsApp.

Guaranteed Spare Parts Availability

Ample spare parts inventory ensures seamless maintenance and replacements.

2-Year Warranty Assurance

All CNC machines include a 2-year warranty for stable operation.

Exceptional Cost-Performance Ratio

Our CNC machines are developed based on models from leading Japanese manufacturers, in collaboration with the Precision Machinery Research Development Center. We have reinforced the structure and adjusted the speed. Currently, the drilling and tapping speeds are comparable to those of Japanese brands. With the quality of Taiwanese manufacturing and a more affordable price, you can achieve the highest performance CNC machines at a competitive cost, ensuring the best return on investment.

Invest in the Future, Make Better Choices

Don't let cumbersome processes slow down your production efficiency. Let us help you enhance your machining competitiveness.