Introduction For Multiple Spindle Head

2020/03/16Multiple spindle head, is a kind of gear box transmission mechanism. It is used to expand a single-spindle machine to be with multiple spindles. In addition to increasing production efficiency, it can also control the position accuracy of holes and holes, Optimize production, reduce the error caused by the workpiece displacement.

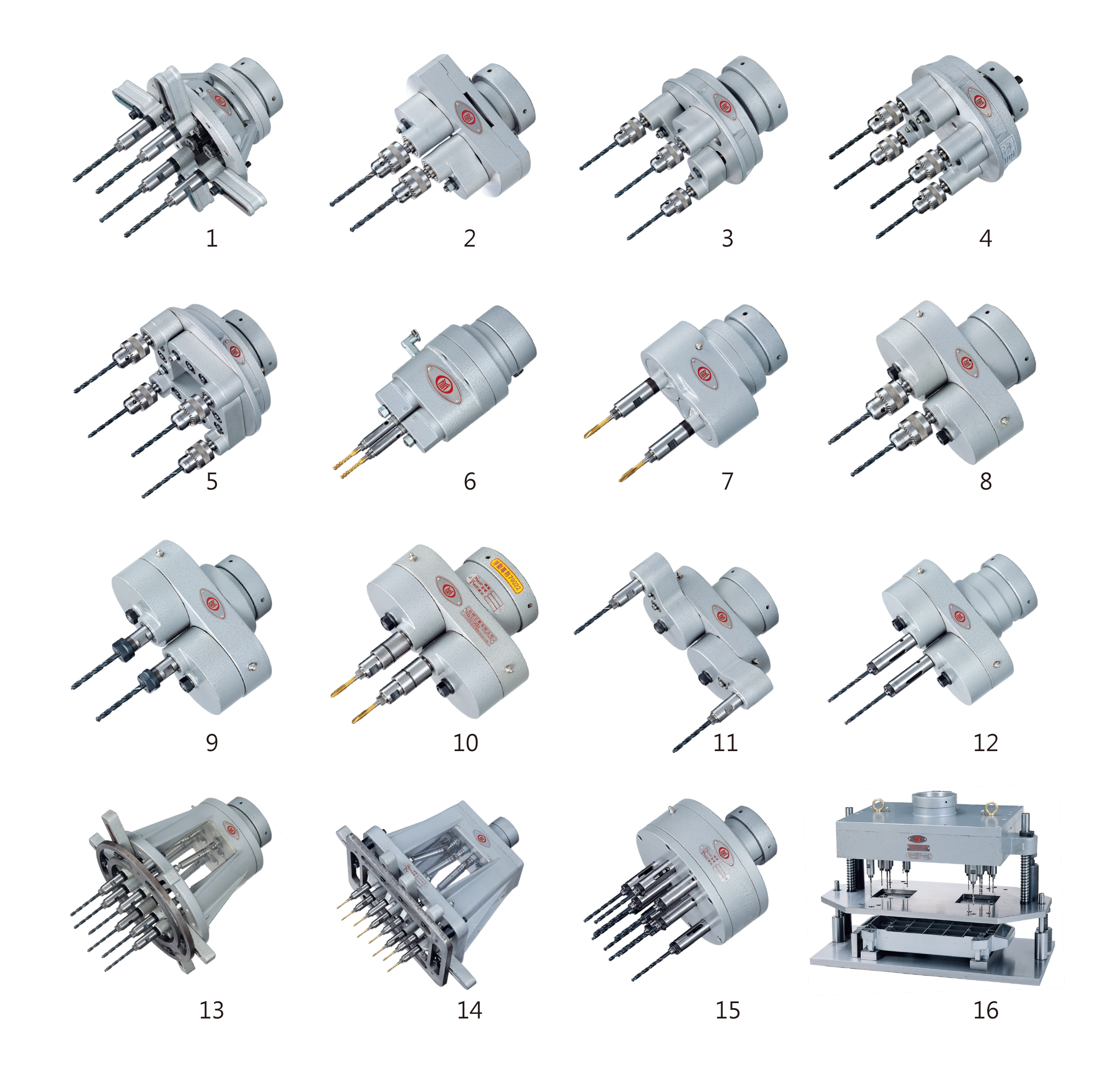

Types of multiple spindle head

Multiple spindle heads can be divided into 2 basic types :

(1) Fixed spindle type :

customized by users’ requirements. The position between each spindle is fixed and cannot be adjusted. It is used for mass production of a single workpiece. It is usually planned together with the spindle guide and fixture for strict control. Repeated production precision, complete the operation goals of large volume and fine quality.

● Customized Machine : https://bit.ly/2IO4UwS

(2) Adjustable spindle type :

The position of each spindle on the head can be adjusted, which is more flexible, than the fixed type, and is mostly used for a small number of diversified productions. The following are some basic types.

● T type - the most commonly used 2-spindle head, small size, light weight, easy to assemble, complete specifications.

See the link for more detail : https://goo.gl/zCqUJL

Video displays please see : https://bit.ly/38TUxlQ

● QU type - Universal joints are used to connect gear box and extending spindles. It is with good flexibility is convenient to adjust spindle positions into a wide range, and make the head to be high strength.

See the link for more detail : https://goo.gl/wVX3Z9

Video displays please see : https://bit.ly/38TUxlQ

● NA and D type are the other two commonly used types, please see the link for more details :

NA Type - https://goo.gl/UdkzPt

D Type - https://goo.gl/DLGP17

(3) The minimum distance between spindles be as small as 10mm. In recent years, the maximum frame we made is 1200X650mm.

Industries to use multiple spindle heads

Multiple spindle heads are widely used in the drilling and tapping of spare parts in various industries.

For example, parts for automobiles and motorcycles: brake discs, steering gears, wheels, differential housings, axle heads, axles, axles, etc., pumps, valves, hydraulic components, solar accessories; bicycle chain racks, pedal brackets , Bicycle and sports equipment tripod; hand tool parts, sheet metal parts, multi-axis tapping, etc ...

In recent years, multiple spindle drilling and tapping machines are more commonly used with high-end CNC milling machines or lathes, and even with robots to increase efficiency for the lack of long production processes on CNCs, and the idle manpower derived from it, making the production line to be more productive.

★ How to order a multiple spindle head

I will need at least 4 items of information to offer a correct multiple spindle heads’ quotation.

(1) Number of spindles

(2) Drilling / Tapping Diameter

(3) Distances between spindles

(4) Material target object made of

Please see the following pages for more information : https://bit.ly/2UbaX43

Machines to install multiple spindle heads

(1) Manual or automatic drilling machines : https://bit.ly/39YWkaz

(2) Manual or automatic tapping machines : https://bit.ly/2ISmPma

(3) Customized machines : https://bit.ly/2Ue8lSO

(4) Basic multiple spindle head installation video : https://bit.ly/2QiH5S4