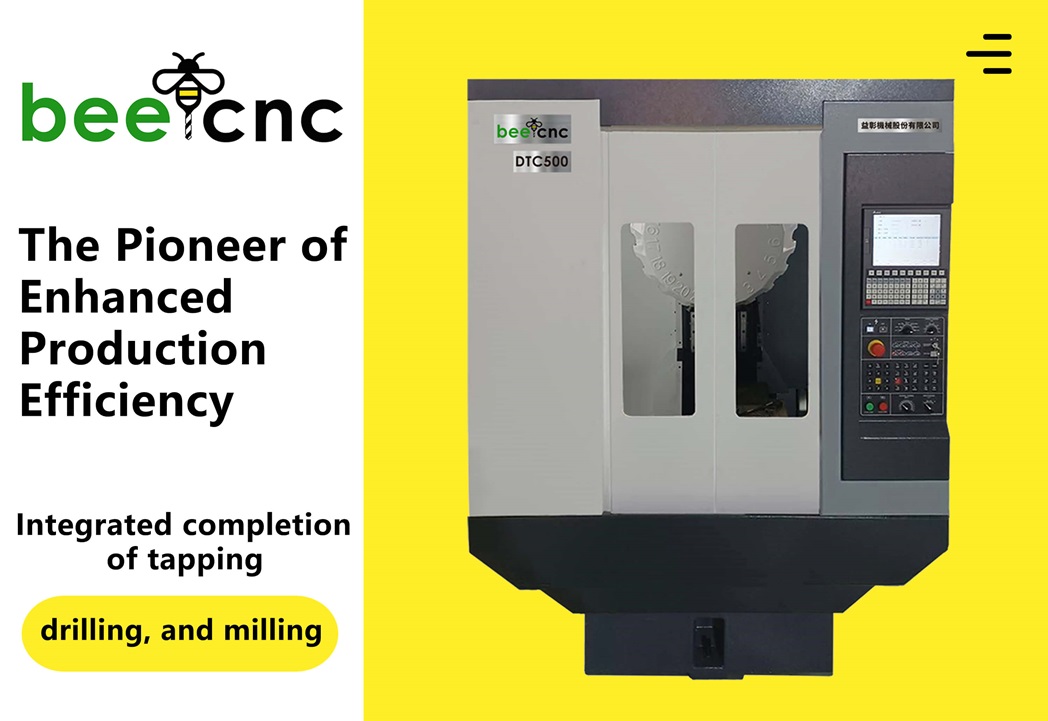

CNC drilling tapping center-The first choice for CNC machine tools

CNC Machine New Breakthrough - Tapping, Drilling, Milling All in One

With 30 years of craftsmanship heritage and innovative integration, we proudly introduce the all-new CNC Drilling and Tapping Machine - BEECNC. Combining drilling, tapping, and milling functions, it not only enhances your processing efficiency but also fully satisfies your diverse needs. It guarantees to inject fresh vitality into your machining business, further elevating your competitiveness.

DESCRIPTION

This is not just a machine, but also an accelerator for your machining business to succeed.

Low axis inertia for more stable high-speed operation.

Lightweight design of the structure, far more energy-efficient than typical CNC machining centers

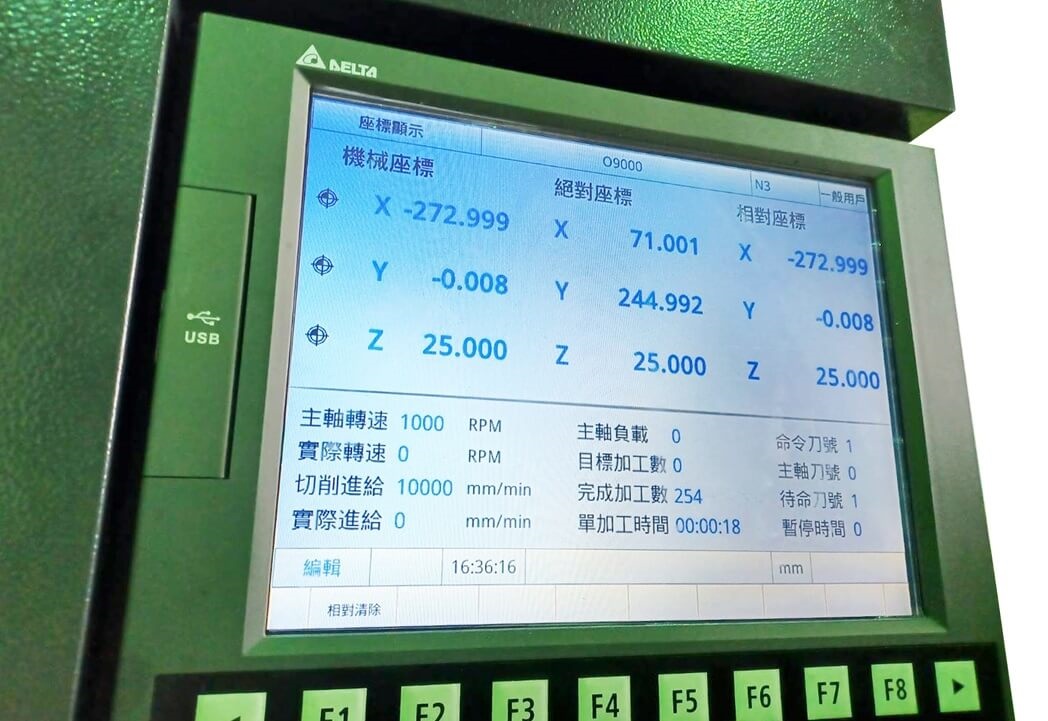

Equipped with Delta controller (with the option to choose Mitsubishi controller).

The machine occupies a small footprint, helping you save even more space.

Compatible with adding a fourth axis (column will be raised).jpg)

9 machine advantages and more powerful functions

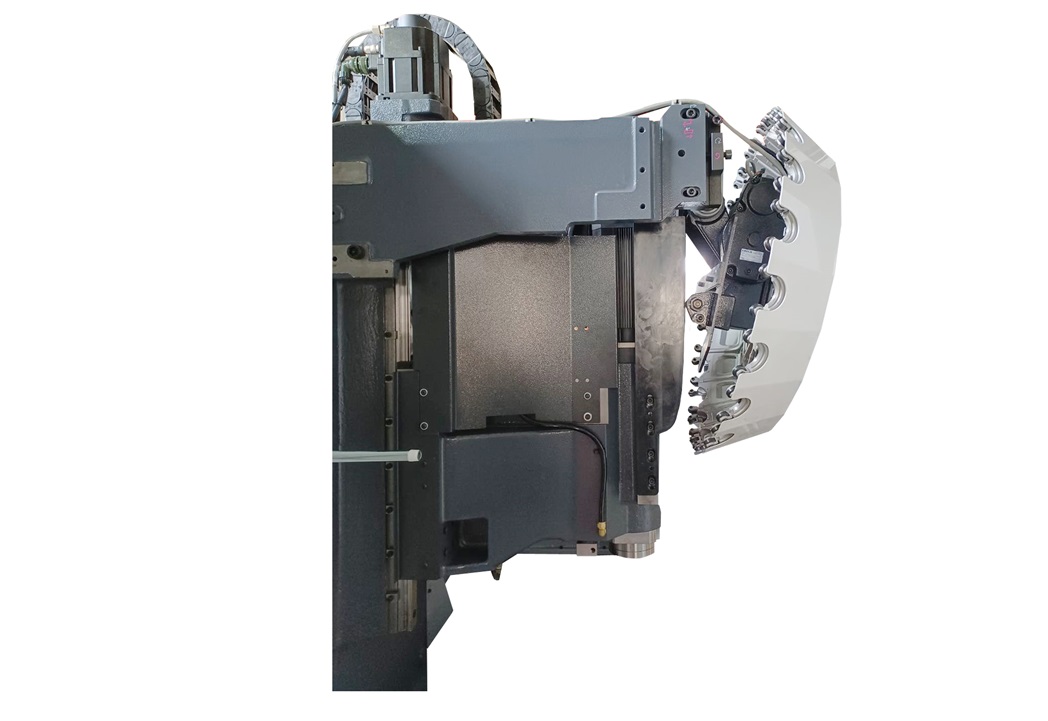

- Can be used to add a 4th axis (the column will be heightened)

- Adjust the machine according to drilling and tapping needs, working faster

- High-speed hole processing-5000 rpm

- Point-to-point can move quickly, delivering 48 meters per minute

- Automatic feeding and unloading system, can be matched with various brands of robotic arms

- Standard equipped with 14 or 21 tool magazines to meet a variety of processing needs at one time

- Overall rigidity increased by 20%

- Provide the design of various special machines, jigs and fixtures, and integrate and plan efficient workstations

- Comply with TS CE international safety regulations

| Mechanical specifications | Unit | DTC-500 | |

| Stroke | X axis robodrill | mm | 500 |

| Y axis robodrill | mm | 400 | |

| Z axis robodrill | mm | 330 | |

| Distance from spindle nose to work surfacerobodrill | mm | 150~480 | |

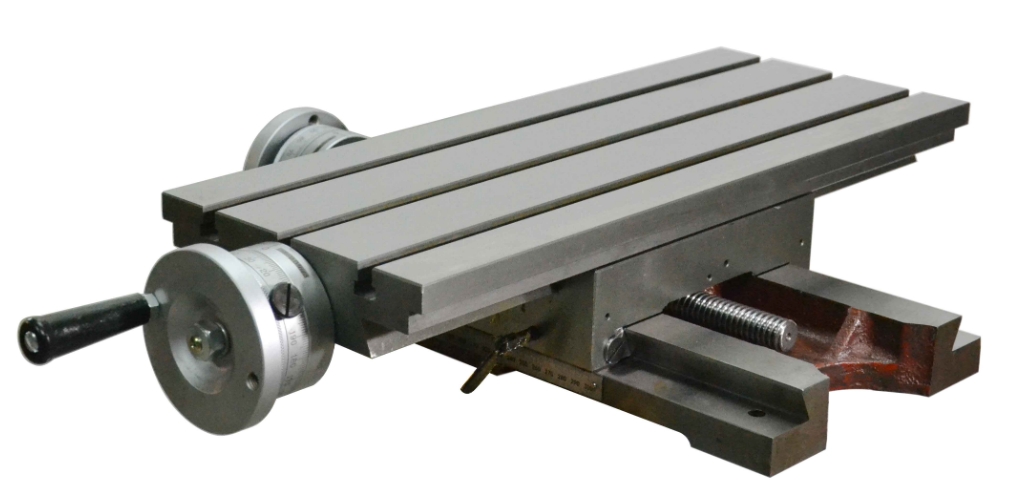

| workbench | Work surface size robodrill | mm | 650*400 |

| Maximum workload robodrill | kg | 300 | |

| Work surface height (above ground) | mm | 800 | |

| Spindle | Taper type robodrill |

BT-30 ( Direct connection ) |

|

| Speed range robodrill | rpm | 12000 / 24000 ( OPT ) | |

| Feed rate | Rapid feed rate robodrill | m / min | X、Y、Z-48m /min |

| cutting feed rate robodrill | m / min | X、Y、Z-10m /min | |

| Automatic tool changing system | Tool specifications robodrill | BT-30 | |

| Maximum tool diameter robodrill | mm | Ø80mm | |

| Numbers of tool robodrill | 14 or 21 | ||

| Maximum tool length robodrill | mm | 250mm | |

| Tool weight robodrill | kg | 1.5sec ( 2KG ) |

Designed for secondary processing companies.

Various casting, forging, and secondary processing factories, specializing in complex drilling and tapping operations, complemented by other lathe-milling machines to reduce production line costs.

Just one machine to fulfill your various needs. Feel free to inquire with us immediately.

Automatic material handling system, compatible with optional robotic arms.

Helping you save more on labor costs

SPEC

HOT SELLING

Professional Fixtures and Jigs Design,Planning customized machine.

| see more | |

|

|

| Multiple Spindle Head (Tap/Drill) | |

|

|

| Drilling Machine | Tapping Machine |

|

|

| Customized Special Purpose Drilling & Tapping Machine | Working Table & Coolant |

|

|

| Accessories | |

Machines are located in Taichung, Taiwan. Interested customers are welcome to visit our factory for machine demonstration.

Or inquire directly at: 04-24930678

Sincerely hope to serve you.